Thermosets in the Utilities Industry

Leave a CommentDue to the excellent material properties with regards to heat and corrosion resistance, and it’s ability to withstand different outdoor elements and weather, parts and components molded from thermosets are commonly used within the Utilities and Power Grid industries. OEMs rely on thermosets for electrical protection to keep lines up without being jeopardized when exposed to aggressive outdoor elements such as snow, heat, and rain. These applications include electrical housings and enclosures that house electronics and wiring, along with traditional circuit breakers and power blocks to not only protect internal components and electronics from damage, but keep the assembly safe to handle and install for line-workers and maintenance. (more…)

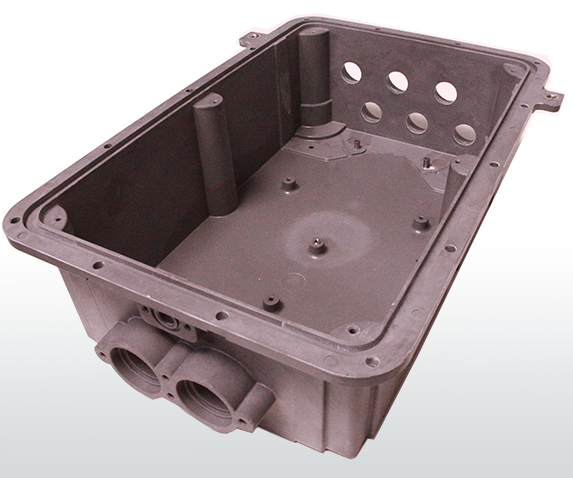

Converting Metal Parts to Thermoset

Leave a CommentEngineers and product designers convert existing products from metals or metallic materials to thermosets in applications for a variety of advantages and benefits to the application. Thermosets offer the moldability of plastics in that they can be molded in a variety of complex geometrical shapes. Whereas metal product applications may require costly secondary machining, lapping, or honing operations to finish a part; thermosets may be molded to tolerances of +/-.005”. In addition to saving on secondary operations, utilizing thermosets in a product design can consolidate multiple parts of an assembly, as well as lower part weight over metal components and assemblies. For high-volume applications, thermosets offer a scalable solution to meet increasing product demand and volume requirements. (more…)