Thermosets Used in EVs (Electric Vehicles)

Comments Off on Thermosets Used in EVs (Electric Vehicles)

Thermoset Molding Materials

Comments Off on Thermoset Molding Materials

Thermoset Injection vs Thermoset Compression Molding

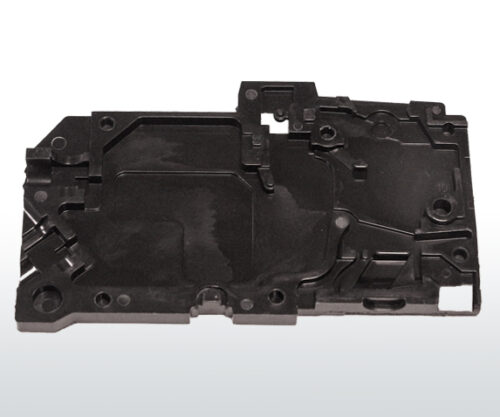

Comments Off on Thermoset Injection vs Thermoset Compression MoldingThermosets are plastic composites used in applications exposed to aggressive elements such as high electrical current, heat and high temperatures, or exposure to chemicals and oils. Thermoset materials can be formed in a variety of molding processes including injection, compression, injection-compression hybrid, insert injection, and transfer molded. Injection and compression molding are the most common molding processes for thermoset parts. Depending on the parts, how they are used, and the specifications to the application, a part may be better suited to be injection or compression molded. (more…)

Automation in Thermoset Molding Processing

Comments Off on Automation in Thermoset Molding ProcessingIn support of high-volume molding programs, Woodland Plastics offers various automation options in its manufacturing production to increase throughput, reduce costs, improving workforce safety, and remain competitive against global competitors. Woodland Plastics has developed and implemented a variety of automation processes into it’s business including both automation during molding such as press-side robotics and end of arm tooling, as well as automation in secondary processes such as automated inline deflash equipment and vision inspection systems. Applications that make sense to implement automation include high volume programs that require excellent efficiency, parts that require 100% inspection, or components needing a high throughput of secondary deflash to keep up cycle times with the molding presses. (more…)