Why Thermosets Are a Go-To Material for Utilities and Power Grid Applications

Comments Off on Why Thermosets Are a Go-To Material for Utilities and Power Grid ApplicationsThermoset materials are a trusted choice across the Utilities and Power Grid industries, thanks to their exceptional resistance to heat, corrosion, and harsh environmental conditions. Designed to endure everything from snow and rain to extreme heat, thermoset-molded components offer long-term durability in demanding outdoor applications.

Can Thermosets Be Recycled?

Comments Off on Can Thermosets Be Recycled?The Answer Is Changing-Here’s How

Exploring the future of sustainable plastics at Woodland Plastics Corporation.

Rethinking Plastics: Why Thermosets Deserve a Second Look

When most people think of plastic recycling, they picture soda bottles, food containers, or grocery bags—items made from thermoplastics. But another class of plastics plays a critical role in modern manufacturing: thermosets.

Known for their strength, heat resistance, and long-term durability, thermosets are widely used in high-performance applications such as automotive components, wind turbine blades, electronics, and electrical systems. For years, their biggest drawback was recyclability—or rather, the lack of it.

That’s changing. Thanks to recent innovations, thermosets are emerging as viable candidates for circular manufacturing. At Woodland Plastics, we’re closely monitoring this transformation and preparing for what’s next.

Thermoplastics vs. Thermosets: What’s the Difference?

Understanding the difference between these two material families helps explain why thermosets were historically excluded from recycling programs.

Thermoplastics:

• Can be melted and reshaped repeatedly

• Easily recyclable through conventional systems

• Common in consumer packaging and disposable goods

Thermosets:

• Cure into a permanent, rigid structure

• Cannot be remelted or reshaped

• Known for exceptional durability, heat resistance, and mechanical strength

• Often reinforced with fiberglass or carbon fiber for added performance

These properties make thermosets ideal for demanding environments—but they’ve also made recycling a challenge. Until now.

The Thermoset Recycling Revolution

New technologies are rewriting the rules and opening doors to sustainable reuse:

1. Mechanical Recycling

Thermosets are ground into powders or fibers and reused as filler in new composite materials. While not full material recovery, this method extends product life and diverts waste from landfills.

2. Chemical Recycling

Advanced processes such as pyrolysis and solvolysis break thermosets down into reusable resins and recovered fibers—even from reinforced composites. This enables the reuse of parts like circuit boards and automotive components in entirely new applications.

3. Thermal Recovery

When direct recycling isn’t feasible, controlled incineration can recover energy from thermosets—supporting waste-to-energy systems and reducing landfill dependency.

Emerging Innovations Worth Watching

The science behind thermoset recycling is evolving rapidly.

Key breakthroughs include:

• Bio-tailored thermosets that degrade with enzymes

• Orthogonal polymerization enabling full material recovery from a single monomer

• Cryogenic grinding for efficient reuse of fiber-reinforced composites

• Dynamic covalent networks (CANs) that allow reshaping and repair of cured thermosets

These advancements are redefining possibilities across the industry. Woodland Plastics is committed to staying ahead of the curve by supporting these efforts and actively exploring future participation.

We remain dedicated to:

• Staying informed on emerging technologies

• Advancing sustainable design and sourcing practices

• Partnering with customers who prioritize circular manufacturing

Why It Matters

Although thermosets account for only 15–20% of global plastic use, they are essential in high-value, high-performance applications.

Recycling them supports:

• Reduced raw material extraction

• Lower greenhouse gas emissions

• More sustainable manufacturing across industries

Recyclability is no longer a barrier to thermoset adoption. With new recovery methods emerging, these high-performance materials are ready for reconsideration. The future of thermosets is not just durable—it’s recyclable.

Let’s Build What’s Next—Together

At Woodland Plastics, we’re committed to helping every customer navigate the evolving landscape of sustainable materials and meet the demands of recyclability, reusability, and compliance with changing industry standards. Whether you’re developing high-performance components or exploring greener alternatives, we’re here to support your goals with clarity, expertise, and forward-thinking solutions.

Have questions about thermosets, sustainability, or material compliance?

Let’s start the conversation. We’re ready to collaborate.

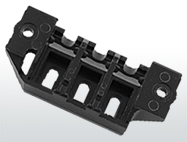

Thermoset Plastics Superior Performance in Demanding Applications

Comments Off on Thermoset Plastics Superior Performance in Demanding ApplicationsThermoset Plastics: The Engineered Advantage Behind High-Performance Manufacturing

In today’s competitive manufacturing landscape, material selection isn’t just a technical decision—it’s a strategic one. At Woodland Plastics, we specialize in thermoset molding because we understand the demands of OEMs operating in high-temperature, high-load, and chemically aggressive environments. When long-term reliability and performance are non-negotiable, thermoset plastics deliver where thermoplastics—including glass-filled nylon—fall short. (more…)