ERP Software for Quality

Using Manufacturing ERP Software for Quality

With a commitment to quality, Woodland Plastics seeks to provide high-quality thermoset parts and components to our customers with an assurance they have been molded and inspected to the product or customer’s quality standard requirements. One avenue Woodland leverages its quality system is through manufacturing ERP software. Manufacturing ERP is a business management software system that streamlines manufacturing operations and data to provide a real-time view of its core business processes. By implementing quality functions through the ERP system, Woodland can accurately record, monitor, and analyze quality-specific data and other quality-related functions.

Real-Time Quality Data

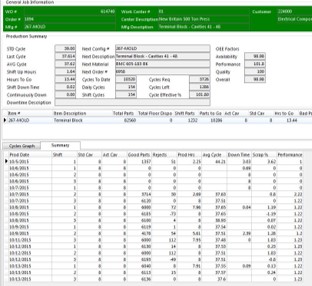

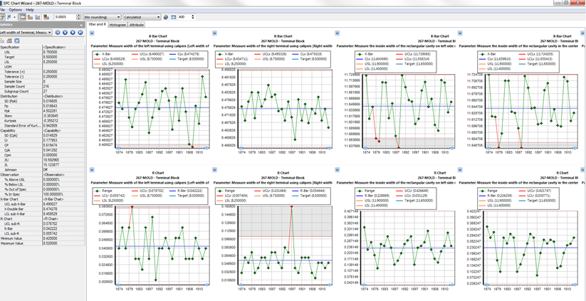

One advantage of leveraging quality functions through ERP software is the ability to utilize production metrics including real time data. Quality teams can record quality measurements and audits through the software, then analyze the data on the back end once all measurements have been imputed into the system. Supervisors and production employees can monitor on-going scrap rates and adjust machine parameters within tolerance if needed. Additionally, reports can be generated on inspection data taken from prior production lots to review past production metrics vs. current. Instead of relying on manual inspection papers that may be costly and require space to store, ERP software allows data to be recorded and stored digitally. Past records can be quickly located for review, and revision updates are able to be implemented immediately. ERP can also send out quality alerts for any process audit failures noted by quality employees or supervisors, allowing the organization to review any quality issues or audit failures jointly prior to shipping product to the customer.

Workforce Training

Another benefit of implementing an expansive ERP system is the ability to easily maintain and manage employee training records. Whether for a new employee joining the organization, or for existing employees to train on molding programs, ERP software allows Woodland the ability to easily manage employee training records, including setting up alerts for re-training intervals. Job instructions specific to each individual molding program can be saved into the ERP system, and work orders can be generated and printed directly from the ERP system to be placed near the correct molding presses, ensuring the most recent revisions and work instructions are being used on the production floor.

Comments are closed