Thermoset Molding Processes: Injection vs. Compression

Choosing the right molding process for your thermoset part may seem daunting, but generally there are indicators in the design and program end-use application that push towards a specific molding process. Like thermoplastics, thermosets can be injection molded or compression molded. Each molding process has its own benefits and disadvantages a thermoset molder and end-customer must understand and balance, before sourcing out a new tool build. Variables such as program annual volumes, material property requirements, part design geometries, and use of molded-in inserts can all affect whether a part is better suited to be thermoset injection molded or manufactured with another molding process.

Thermoset Injection

Using an injection molding process is very common in many industries for thermoset components. Thermoset injection molding process offers a very fast cycle time compared to a compression or transfer molding process, allowing a thermoset molder to produce a higher throughput of production in a day or shift. Industries such as automotive and home appliance rely on thermoset injection molding process for high-volume thermoset components that can produced and shipped to customer plants quickly. A thermoset injection molding process may save as much as 50% of machine time per shot with a faster cycle time compared to a thermoset compression molding process, allowing molders to produce high quantities of thermoset components per day in multi-cavity tools. High-volume programs aren’t the only type of projects that benefit from a faster cycle time, as thermoset injection molded parts use up less machine time over a single production run, lowering unit pricing for customers and freeing up machine time to run other jobs.

Thermoset injection molding may also allow greater design flexibility for engineers and product designers. With thermoset injection, parts are fed material through a gate via a sprue and runner(s). Having flexibility with gate design allows designers and molders to move parting lines, improve material flow, and allow for more evenly dispersed material fillers, such as glass and mineral fibers. Designers are able to more easily create complex shapes and geometries within their component designs due to the flexibility of gating that thermoset injection process offers over a thermoset compression process.

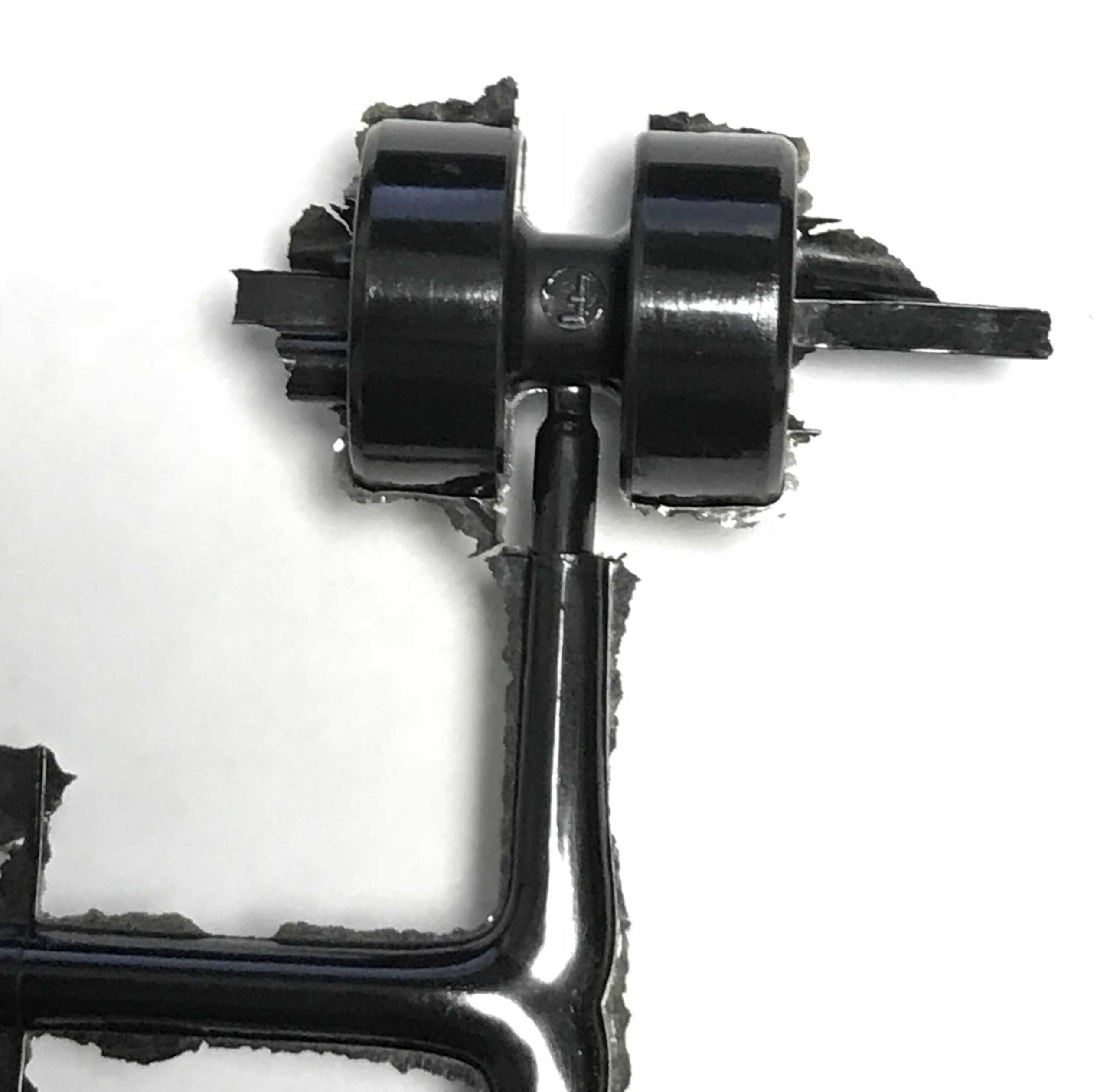

If thermoset injection molding process provides higher throughput and overall lower unit pricing, why choose any other process? Although thermoset injection molding is able to quickly and efficiently mold a large quantity of thermoset parts, it may not be the best choice for your application. Depending on the design of the part, some components cannot have a knit line, which is where the material meets together and creates a knit or weld line. The knit line is generally opposite the gate in thermoset molding, and may also create a weak spot in the spot. Component designs that cannot have any knit lines whatsoever may be better suited to compression mold as the compression molding process does not require a gate location; the part cavity can be fed material directly with a hand placed “charge” of material, instead of going through a screw and barrel, through a sprue, and into a runner/gate to feed the part cavity with material with a thermoset injection process. Without a gate location, there is no knit lines created opposite the gate.

Thermoset Compression

Using a thermoset compression molding process offers distinct advantages and disadvantages from a thermoset injection molding process. In thermoset injection, material is pushed from a hopper (phenolic material) or hydraulic stuffer (bulk molding compound/BMC material) into a screw and barrel to preheat prior to being injected into a hot mold. When material is pushed through the screw and barrel, the glass fiber fillers that make up some thermoset materials are chopped up and dispersed even further. In some applications this would be great as glass is evenly dispersed throughout the part, providing uniformity of the material properties. In other applications, this may actually be a hinderance. When the glass fiber filler is chopped up in the screw and barrel in an injection process, the material may lose some of its strength characteristics. This may be fine for most applications, but in an application where the strength of a material is the most critical property requirement, using a compression molding process could be a better solution than injection molding. With compression process, the glass fiber filler is not further chopped, and may not be evenly dispersed, allowing the opportunity to make some areas of the part stronger than others by strategically placing the “charge” or amount of material to be molded in the compression mold at specific areas.

Alternative to the benefits of a thermoset injection molding process, a thermoset compression process is not as suitable as thermoset injection for high-volume programs due to a slower molding cycle time, creating lower throughput and yield of production per day than an injection process. Compression molding also requires an operator or robot to hand-load material and take out parts from the mold, whereas thermoset injection machines can more commonly mold automatic, with no operator required to stay at the molding station to “demold”, or remove parts form the mold. Material can be fed into a hopper or stuffer periodically with an injection process, whereas compression molding requires an operator or robot to hand load material into each and every shot, raising labor costs and unit pricing to customers.

In conclusion, there are general indicators as to whether a thermoset program is better suited to be injection molded or compression molded. High volume programs with high cavitation tooling may make sense to design into a thermoset injection process due to thermoset injection processes’ faster cycle times and throughput. In addition, programs that are unit price-sensitive should likely be first explored with a thermoset injection process and design to maximize economies of scale and keep part costs low. A thermoset compression molding process on the other hand may lend itself towards applications requiring even higher strength characteristics than a thermoset injection material may offer, or for extremely large parts not possible to injection mold with standard equipment and molding press. Although these are common indicators, application end-use and future program requirements should always be considered and reviewed when deciding which thermoset molding process is best for your product application.

Comments are closed