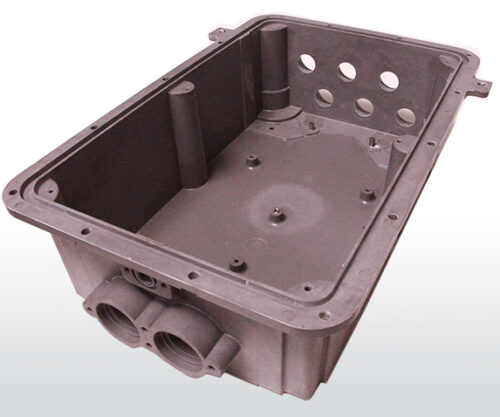

Converting Parts from Metal to Thermoset

Engineers and product designers convert the design of existing parts and components from metals or to thermoset plastics in applications for a variety of material property advantages and benefits to the application. While metal components may require costly secondary machining operations to manufacture a part, thermosets may be molded into complex geometries and shapes. Incorporating thermoset materials into a product design may allow for consolidation of multiple parts of an assembly, as well as reduce overall weight of a product or assembly compared with metallic parts. For high-volume applications, thermosets offer a highly scalable solution to meet increasing product demand and volume requirements with low waste.

Cost Advantages

While tooling costs for thermoset injection molding may be higher up front than tooling for cast metals, the tooling longevity or life expectancy for thermosets can reach over 1,000,000 cycles, positioning thermosets as a cost-effective material option for high-volume program applications that need to scale to meet increasing product demand.

Material Performance

In electrical applications, thermoset composites offer high dielectric strength and insulation performance, low arc & track, and some thermosets are UL V0 or 5VA rated for flammability resistance. With its strong insulating properties, thermosets can also dampen or reduce vibration and sound of a product over metal counterparts.

Comments are closed