Dedicated Mold Base vs. MUD Inserts

In order to produce a plastic injection molded part, a mold or tool must be built to manufacture the part. How the mold or tooling is designed and built is one question both molders and OEMs must ask. In order to determine the best way to design and build a mold, both parties must discuss part design and the geometry of the part, quantity of parts required per year, and the life expectancy of the part or program. These factors can determine whether a dedicated mold base or MUD (Master Unit Die) inserts are better suited for the program.

What’s the difference?

A dedicated mold base is a full mold – it includes both a cavity and core side and may be one or multiple cavitation. A dedicated mold base is only limited in size to the molding press it will run in.

In contrast, MUD inserts are only the insert portion and require a standard MUD frame to run in. MUD inserts are limited in size to the footprint of the MUD frame they are to run in, so MUD inserts will generally be limited to running one or two cavities at a time in a MUD frame.

Benefits of a Dedicated Mold Base

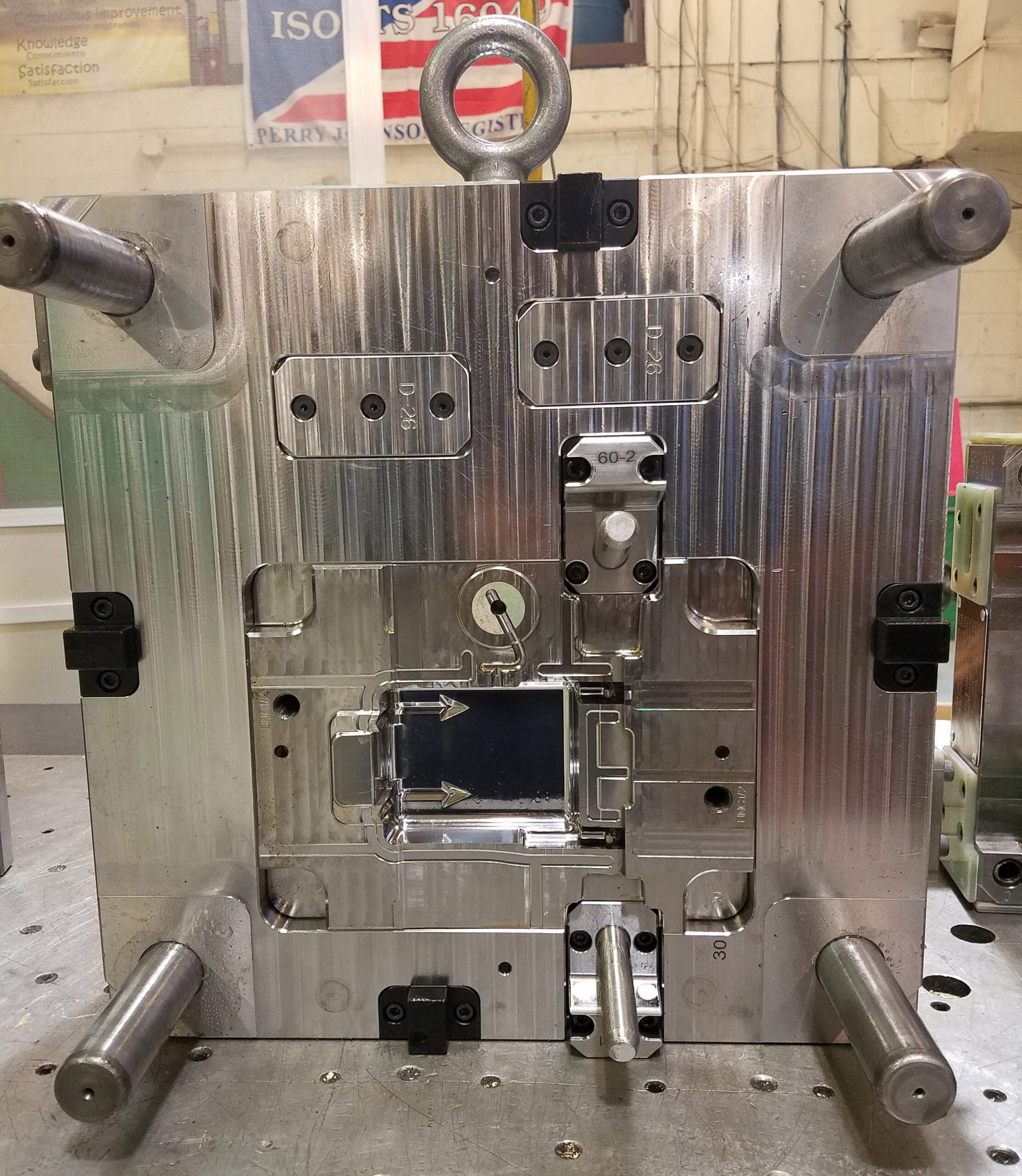

Dedicated Mold Base

For parts that have a long life expectancy or high annual volumes, Dedicated Mold Base[/caption]it may make more sense to have a dedicated mold base built vs. MUD inserts. Dedicated mold bases offer a higher mold life than MUD inserts, allowing a molder to run more cycles or parts throughout the life of the mold before new tooling is required. Additionally, for parts that are large or may have an intricate design, MUD inserts may not offer enough space in a MUD frame to accommodate the part or mold design.

Benefits of MUD Inserts

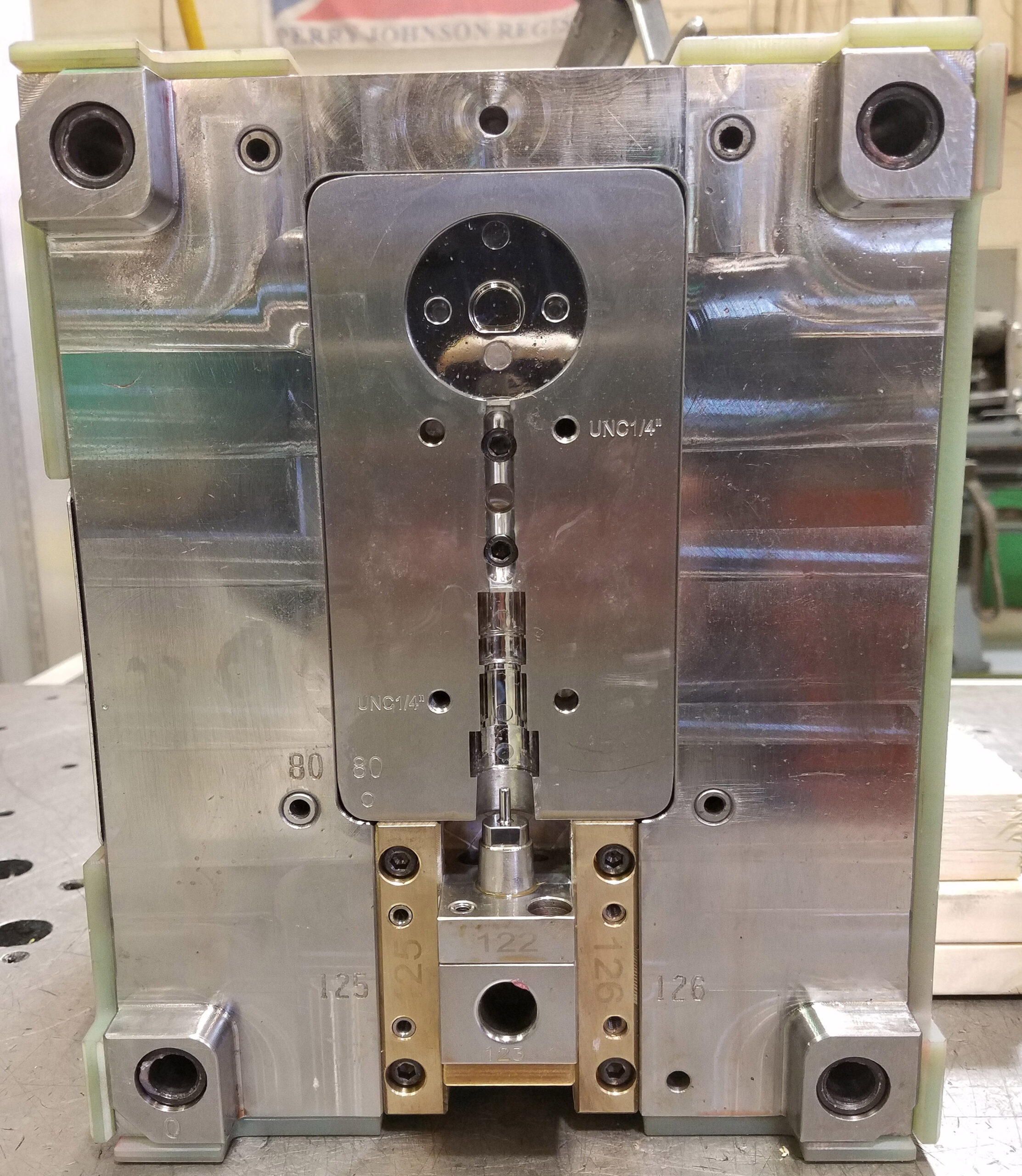

MUD Inserts within MUD Frame

Smaller parts with lower annual volumes may benefit more using MUD inserts vs. a dedicated mold base. Because MUD inserts comprise of only a portion of a dedicated mold base, the cost for MUD inserts may be substantially more attractive to customers vs. a dedicated mold. MUD inserts may also be used in prototyping projects where a customer wants to keep investment costs down before entering a production stage.

Comments are closed