Deflashing Thermosets

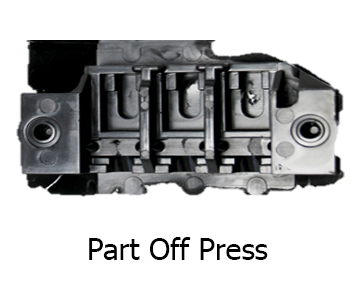

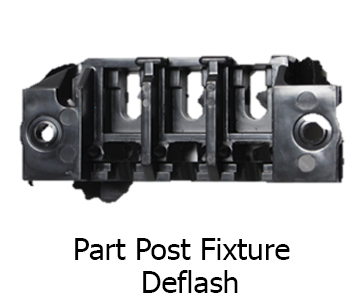

One of the main differences between molding thermosets and thermoplastics is that thermoset molded parts must be deflashed after they are formed, whereas thermoplastics are molded without flash. Flash is excess material from the material needed to form a full part. In order to mold a full part, thermosets must be molded with flash, otherwise the part integrity may be jeopardized by shorts, burns or other molding defects. Regardless of whether a molded thermoset part is molded into basic or complex geometries, it will always require a secondary deflash operation. Removing the excess flash can be done in a variety of ways, depending on what is most suitable to the part and volume requirements.

Deflash operations can be performed either manually or automatically with deflashing equipment. Automated deflash equipment can be a batch deflash process where a set amount of parts are put in a tumbling or wheelabrating machine and tumbles the parts to remove flash. Another option for automated deflashing is inline deflash equipment where parts are continuously put on a conveyor and ran through tumbling equipment. For manual processes, operators can remove flash by hand using a cotton or wire mesh glove, or use hand tools such as files or cutters. For higher volume programs, automatic deflash operations can be much more efficient and comfortable on labor.

Comments are closed