Heat Resistance in Molded Thermosets

As engineers and designers continually try and maximize their product application’s performance, thermosets are becoming more attractive to implement into component designs and assemblies. Molding thermoset materials such as a phenolic or bulk molding compound (BMC) polyester or vinyl ester provides an end part with better protection against challenging and aggressive environments including applications exposed to high temperatures and heat. Whereas engineered thermoplastics such as nylon (PA6/ PA66) and ABS may degrade and disfigure when exposed to excessive temperatures, creating an opportunity for product failure in the field, molded thermosets offer heat deflection properties up to 500F and even above in some formulations to protect components from damage or failure.

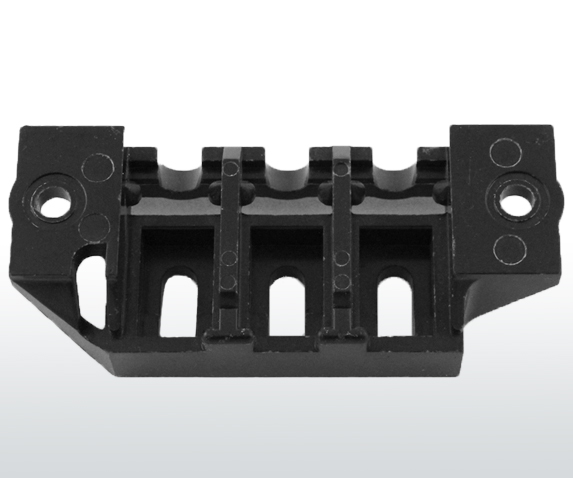

One area of review when designing a molded plastic part is the level of heat or high-limit temperature the part may experience during operating use or in the field. Applications such as housings and covers must remain dimensionally stable under high temperatures to protect internal components from being damaged. Additionally, electrical insulator applications require a tough material to limit heat dissipation into internal electrical components or cabling. Grill handles, oven components, and bases or covers for small consumer cooking appliances all rely on thermosets to not only protect internal components but allow safe handling for the customer and product user. Outside of high-cost aerospace materials, thermoplastics do not offer the same level of heat resistance properties as a molded thermoset will. In automotive applications, some powertrain or transmission parts may also see high operating temperatures from the engine or transmission, which can even be magnified in the summer months. For many of these applications, components must remain durable and not fatigue or disfigure throughout the life of the product its used in.