Injection Molding BMC Thermosets

BMCs, or Bulk Molding Compounds, are a type of thermoset material that are unsaturated polyesters or vinyl esters, and may be injection molded on horizontal molding machines. The properties of BMC molded parts exhibit exceptional dielectric strength, electrical insulation, heat resistance, and chemical resistance lending BMCs to be molded in a variety of safety-critical applications and component assemblies within the Electrical, Automotive, and Industrial markets. In its raw state, BMC resembles a play-dough like form and is filled with glass fibers or mineral fillers dispersed within the resin system to provide strength. Molding wise, BMCs are more commonly injection molded, but can also be compression or transfer molded. Injection molding BMCs require the use of a stuffer or ram to help inject material into the screw and barrel to preheat and plasticize prior to injecting into the molds.

BMCs, or Bulk Molding Compounds, are a type of thermoset material that are unsaturated polyesters or vinyl esters, and may be injection molded on horizontal molding machines. The properties of BMC molded parts exhibit exceptional dielectric strength, electrical insulation, heat resistance, and chemical resistance lending BMCs to be molded in a variety of safety-critical applications and component assemblies within the Electrical, Automotive, and Industrial markets. In its raw state, BMC resembles a play-dough like form and is filled with glass fibers or mineral fillers dispersed within the resin system to provide strength. Molding wise, BMCs are more commonly injection molded, but can also be compression or transfer molded. Injection molding BMCs require the use of a stuffer or ram to help inject material into the screw and barrel to preheat and plasticize prior to injecting into the molds.

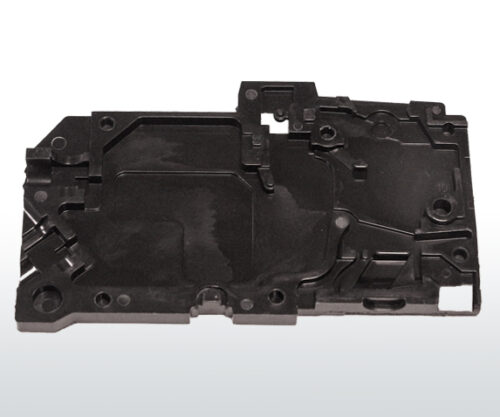

Electrical components such as terminal blocks, connectors and circuit breakers are molded from thermoset BMCs due to these desirable electrical properties, keeping the product assembly and components safe even during a power failure or electrical trip. Automotive transmission and powertrain components utilize heat resistance and chemical resistance properties of BMC for parts exposed to automotive fluids, oils, and grease. Likewise, the high temperature resistance allows BMC parts to remain strong and durable even within applications experiencing high operating temperatures.

Electrical components such as terminal blocks, connectors and circuit breakers are molded from thermoset BMCs due to these desirable electrical properties, keeping the product assembly and components safe even during a power failure or electrical trip. Automotive transmission and powertrain components utilize heat resistance and chemical resistance properties of BMC for parts exposed to automotive fluids, oils, and grease. Likewise, the high temperature resistance allows BMC parts to remain strong and durable even within applications experiencing high operating temperatures.