Protecting Electrical Applications with Thermosets

While thermoset molding materials are used in a variety of end-use industries, one of the larger industry users of molded thermoset parts is within the electrical industry. Parts molded in a thermoset material not only exude excellent electrical properties to remain strong and durable over the life of a part, but the electrical performance properties of thermosets also enhance the safety of end products and assemblies. With superior electrical properties over many engineered thermoplastics, thermosets are an excellent, low-cost material choice for electrical parts or assemblies that may experience electrical voltage, elevated temperatures, or thermal shock.

Safety and Protection

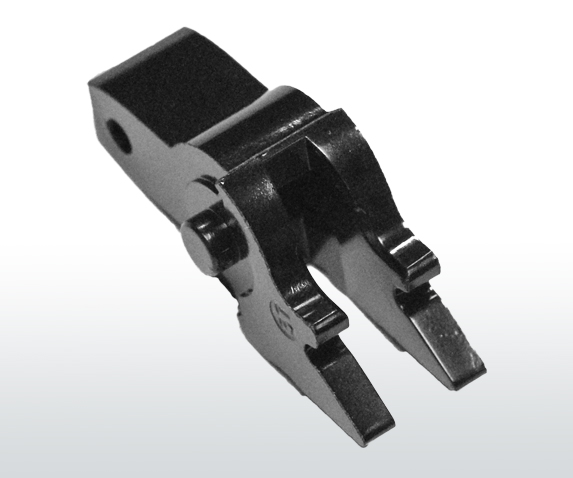

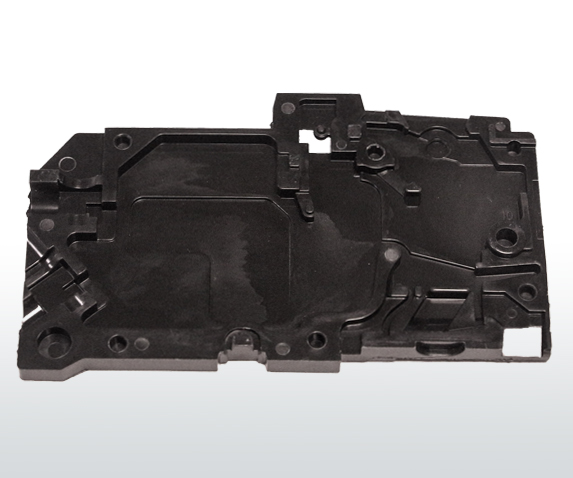

Electrical components and assemblies require materials that not only protect internal components and electronics, but also allow for safe handling by users and service technicians. Molding electrical parts with thermosets provide a host of safety benefits. Thermosets provided excellent resistance to arc and track, protecting both the part and internal components from potential product failure or burning. Components requiring a thermoset due to potential electrical arc or track damage include switches, circuit breakers, contacts, and fuses. Aside from arc and track resistance, thermoset molded parts are heat resistant up to 400-500 degrees depending on material formulation, allowing the parts to continue operating in high temperatures or under thermal shock conditions without degradation. Many thermoset material formulations are also UL 94 rated for flammability with a V0 or 5VA designation. Lastly, thermosets are used in many applications as electrical insulators to resist the flow of electrical charges or currents that can cause physical or chemical damage or degradation to parts and assemblies.