Thermoset Injection vs Thermoset Compression Molding

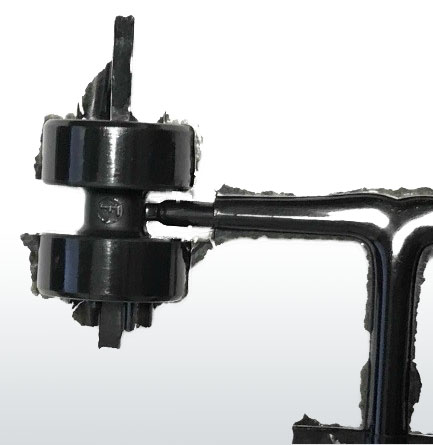

Thermosets are plastic composites used in applications exposed to aggressive elements such as high electrical current, heat and high temperatures, or exposure to chemicals and oils. Thermoset materials can be formed in a variety of molding processes including injection, compression, injection-compression hybrid, insert injection, and transfer molded. Injection and compression molding are the most common molding processes for thermoset parts. Depending on the parts, how they are used, and the specifications to the application, a part may be better suited to be injection or compression molded.

Why Injection Mold?

Injection molding thermosets allow for parts to be produced in a high volume/ high throughput setting with faster cycle times than a compression molding process. By molding parts quicker, molders use less machine time resulting in a lower unit price on the finished parts. Parts in the electrical, automotive, appliance, and industrial settings with high volume and EAU requirements rely on thermoset injection molding process in order to produce more parts at a set interval time. Choosing an injection molding process can quicken cycle times by twice as much as the throughput of a compression molding process. Injection molding also allows for complex geometries with the ability to implement slides or side actions in the mold.

Why Compression Mold?

Compression molding is suitable for lower volume parts that do not need a high throughput or fast cycle time. Compression molding generally offers a higher unit price for the parts, but may offer a lower tooling cost due to minimal cavities and the absence of gating/gates. Additionally, for parts that require very high strength, a compression molding process offers the highest strength properties to a molded part.