Thermoset Molding Materials

Thermoset plastics, or composites, differ from thermoplastic materials. While thermoplastics are more more common molding materials for general plastic use, thermosets are a material of choice for challenging applications exposed to electrical current, high temperature, or aggressive chemicals. In similar application settings, thermoplastics will degrade, jeopardizing the integrity of the molded part. Thermosets remain dimensionally and chemically stable within these elements. What materials are commonly used in thermoset molding?

Thermoset plastics, or composites, differ from thermoplastic materials. While thermoplastics are more more common molding materials for general plastic use, thermosets are a material of choice for challenging applications exposed to electrical current, high temperature, or aggressive chemicals. In similar application settings, thermoplastics will degrade, jeopardizing the integrity of the molded part. Thermosets remain dimensionally and chemically stable within these elements. What materials are commonly used in thermoset molding?

Thermoset Molding Materials

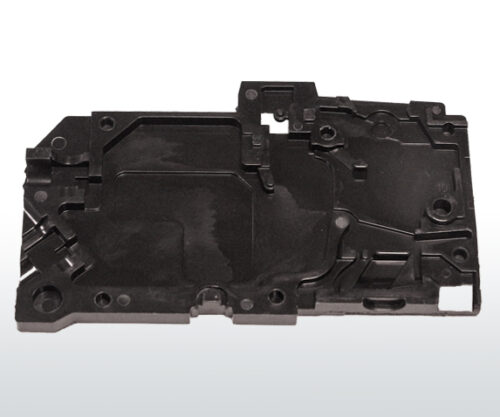

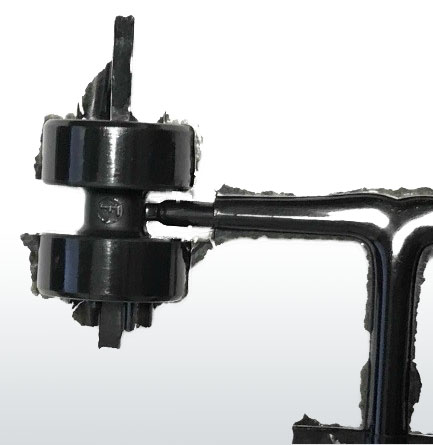

Two of the most common types of thermoset or thermosetting materials are phenolics / phenolic molding compounds, and bulk molding compounds or BMCs. BMCs are unsaturated polyesters and vinyl esters. Both materials exude exceptional electrical insulation performance, allowing the materials to be used in molding applications for electrical housings, circuit breakers, terminal blocks, and other components that see electrical current. Additionally, both offer chemical resistance to oils, automotive fluids, and other chemicals. Lastly, both phenolics and BMCs provide molded parts with a high temperature deflection of 400-500F, allowing parts to remain durable and stable even when exposed to high heat. These materials differ from engineered thermoplastics in the above properties that allow thermoset molded parts to remain dimensionally and chemically stable, keeping internal components protected and allowing safe handling of the product assembly for users.

Two of the most common types of thermoset or thermosetting materials are phenolics / phenolic molding compounds, and bulk molding compounds or BMCs. BMCs are unsaturated polyesters and vinyl esters. Both materials exude exceptional electrical insulation performance, allowing the materials to be used in molding applications for electrical housings, circuit breakers, terminal blocks, and other components that see electrical current. Additionally, both offer chemical resistance to oils, automotive fluids, and other chemicals. Lastly, both phenolics and BMCs provide molded parts with a high temperature deflection of 400-500F, allowing parts to remain durable and stable even when exposed to high heat. These materials differ from engineered thermoplastics in the above properties that allow thermoset molded parts to remain dimensionally and chemically stable, keeping internal components protected and allowing safe handling of the product assembly for users.