Thermoset Plastics for Electrical Products and Applications

Curious which industries use thermoset materials within molded components and product assemblies? While many different end markets and consumer industries rely on thermosets’ material property benefits for manufactured components and products, the electrical industry is one of the largest end-use industries for molded thermoset parts. Electrical products benefit from molded thermosets’ superior electrical properties at competitive price points for raw material compared to engineered thermoplastics. Engineers and product designers utilize thermosets into component designs and product assemblies not only for material performance, but also with product safety assurance in mind.

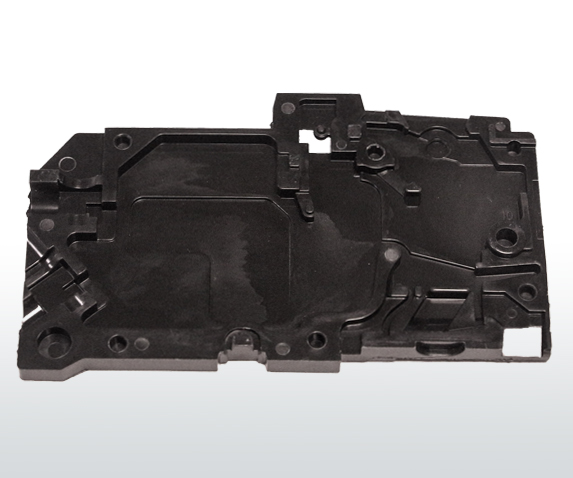

From a material property standpoint, thermosets offer excellent electrical performance such as dielectric strength and electrical insulation over thermoplastics. This strong electrical insulation protects product assemblies and internal components from risk of damage from electrical charge. Additionally, thermosets are resistant to electrical arc and track, and many thermoset formulations have passed stringent UL testing to be rated for flammability suppression. Parts molded from thermoset materials remain durable and strong even when exposed to electrical charge, high temperatures, or thermal shock. Electrical applications that commonly incorporate molded thermosets include electrical housings, terminal and fuse blocks, circuit breakers, connectors, and other electrical components housing electrical wiring, terminal or pcb boards, or other electrical instruments.

Comments are closed