What Materials are Thermosets?

Thermoset Plastics are a niche grade of molding material compared to common engineered thermoplastics such as PA66 (nylons), ABS, Polypropylene. While thermosets are much less known, they have actually been around much longer. The first plastic material created, bakelite, created by Leo Baekeland in 1907 was a type of thermoset composite. Despite use dating back a century ago, thermosets are much less widely used in molding applications. For applications that do not require stringent material properties, many designers and OEMs look to thermoplastics, which are commodity grades that can be remelted and remolded. Using thermosets on the other hand require an application needing a material with much stronger properties such as temperature and corrosion resistance, high electrical strength, and low deflection properties.

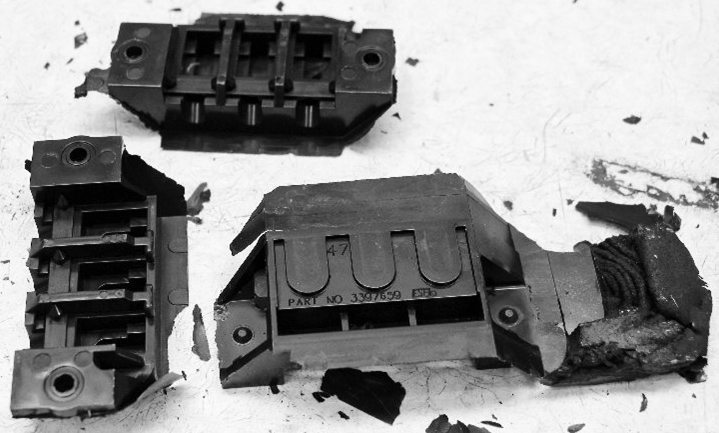

Common thermoset composites, or thermoset plastics, include phenolic molding compounds, bulk molding compound (BMC) which can be an unsaturated polyesters and vinylesters, epoxy, and diallyl phthalate (DAP), and sheet molding compound which is similar to BMC but offers higher strength and is traditionally compression molded. These thermoset materials can all be processed with injection, compression, injection-compression hybrid, transfer, and insert molded. Each thermoset material has various advantages over the other types of thermoset materials, however in general, most all thermosets offer superior heat and chemical resistance compared to engineered thermoplastics. While Phenolic, DAP, and some Epoxies are all compounded into a similar state to thermoplastics as granular form, BMC is extruded into a playdough like form that requires a stuffer system to inject material from the molding machine into the mold for injection molding processes.

Comments are closed