Why Flash is Required in Thermoset Molding

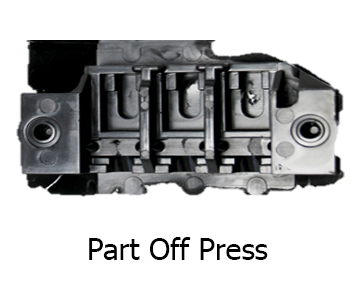

One major difference between thermoset molding and thermoplastic molding is the appearance of parts coming out of the press. While both thermoset and thermoplastic materials may be formed using similar molding processes (injection, compression, or insert molded), thermoset molded parts must be molded with excess flash, or plastic material, around the parts in order to be fully molded, or cured.

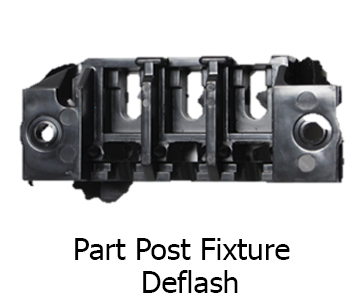

This excess flash in a thermoset molding process is to be removed in a secondary operation either with a tumble process or manually by hand. In thermoplastic molding, parts are molded into the final geometry without any excess flash to remove. Where flash is required in thermoset molding, it is a defect in thermoplastic molding.

Depending on the part and application, thermoset molded parts may be deflashed in a variety of ways – from a manual hand deflash using files and fixtures, to automated tumble deflashing equipment such as wheelabrators, finmac machines, inline deflash tumblers or even a combination of deflash tools and equipment. A wheelabrator is an automated machine used to tumble parts around while simultaneously blasting bits of walnut shells to take away flash from the molded parts. Similar to a wheelabrator, finmac machines use the same process, but use bits of thermoplastic media to deflash parts instead of walnut shells.