Thermosets in Cold-Weather Applications

Thermosets, or thermosetting plastics, have always been known in the plastics industry as heat-resistant materials. Many of the end-use applications thermoset components are used in may see high temperatures or excessive heat during application use. While thermosets remain dimensionally stable in high-temperature applications, it is not the only temperature-specific property benefit of using molded thermosets. In addition to heat resistant properties, components molded from thermoset materials such as bulk molding compounds (BMC) and phenolic resins offer excellent material performance in cold and sub-freezing environments just as well as high-temperature environments.

Strength in the Cold

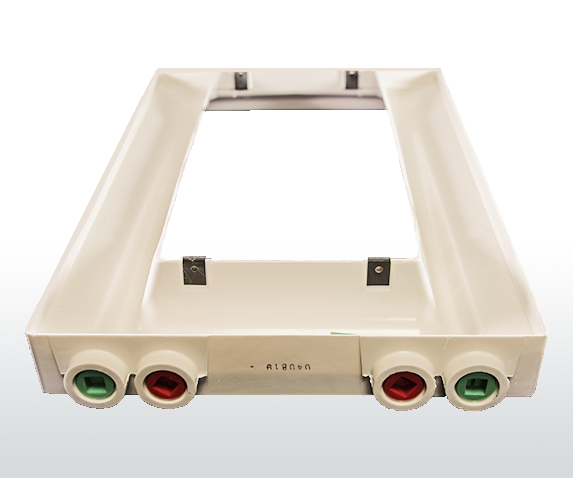

Thermoset plastics or composites are used in outdoor applications due to their ability to remain dimensionally & chemically stable in challenging environments. Whether a component is used or installed in the Arizona desert heat or Alaskan winter, outdoor components must remain durable through different climates throughout the life of the part, even if it’s product life spans several years or even decades. Molded thermosets remain durable down to -40° below zero; making thermosets suitable for applications used in outdoor lighting, HVAC, outdoor grill and cookware, utilities, and automotive industries.

Exposure to Wind, Rain, Sleet, Snow

Not only must thermoset components remain durable in sub-freezing temperatures, but they must also withstand extreme weather conditions where parts may be subject to torrential rains, heavy winds, or frigid sleet & snow. Thermosets stand up to all the above conditions to keep product assemblies working properly whereas components molded with thermoplastic materials may see physical degradation or outright product failure.

Comments are closed