Chemical Resistance in Thermosets

As a custom thermoset phenolic and BMC molder, Woodland Plastics manufactures thermoset components for a variety of customers and end-use applications. Many of our customers’ buyers and engineers are familiar with the heat resistance properties of thermosets, and its ability to remain dimensionally stable within high temperatures. A less common, but just as important material property benefit in using a phenolic or BMC polyester/vinyl ester material in a product design is thermosets’ superior chemical resistance compared to thermoplastics, such as nylons, ABS, or polypropylene.

In general, thermoset materials may be resistant to weak acids, weak alkaline solutions, alcohols, esters, ketones, ethers, hydro-carbons, chlorinated hydrocarbons, benzene, motor oils, brake fluids, gasoline, mineral oils, animal and vegetable oils and fats. Additionally, some recent testing from a material supplier has indicates thermosets have good resistance to xylene, glycerin, and salt water.

Automotive Fluids

Thermosets are widely used in automotive transmission components that are continuously exposed to harsh chemicals such as oils, gas, transmission, brake, and cooling fluids. Whereas thermoplastics such as a glass-filled nylon will degrade over time when exposed to certain chemicals, thermoset components remain dimensionally and chemically stable over the life of the component, providing a peace of mind products will not break down or degrade in such environments.

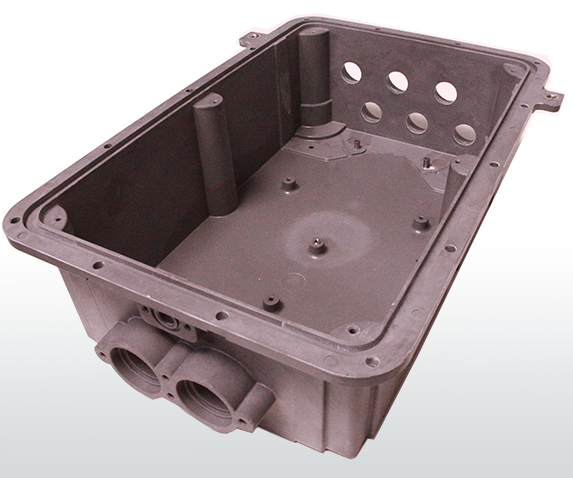

Ground Water Run-Off

In outdoor or underground environments, applications may see ground water run-off that could potentially be contaminated with a number of different chemicals or salts, especially after a geographic area experiences heavy rain or flooding. Underground and outdoor enclosures or electrical housings are not negatively affected nor will they corrode, keeping internal electronics protected from significant damage.