Use of Thermosets in Corrosive Environments

With superior material property performance over thermoplastics, thermosets are an excellent material option for applications exposed to challenging environments. One of the main material benefits molded thermosets exude is strong resistance to corrosion and rust. Whether an application is exposed to outdoor conditions with high humidity or moisture, or used to house electrical components, thermosets offer excellent protection against corrosion. When directly exposed to water or fluid conditions, thermosets have a very low water absorption compared to thermoplastics, ensuring molded parts keep the same mechanical properties and geometry as they did right after molding. Whether an application is exposed to running water, moisture, condensation, or steam; thermoset materials provide a stable and durable material option to keep parts and components working throughout the life of the product assembly.

Anti-Corrosive in Outdoor Applications

Thermosets are commonly used in a variety of outdoor applications in part due to strong resistance to moisture and corrosion. Molded thermosets will not degrade or rust in wet environments, combating rain and moisture so the molded thermoset components look and perform just as well as they did off the mold. Outdoor grill handles and grill shelves are not affected when left outside constantly whereas a metal grill handle or shelf will eventually show corrosion and rust if not protected. Additionally, outdoor LED light housings and other electrical housings use thermosets in part designs for expanded protection for internal electrical components. Thermoset light housings or electrical enclosures can be stored outside without fear of internal electrical components failing from moisture or rain exposure.

Anti-Corrosive in Indoor Applications

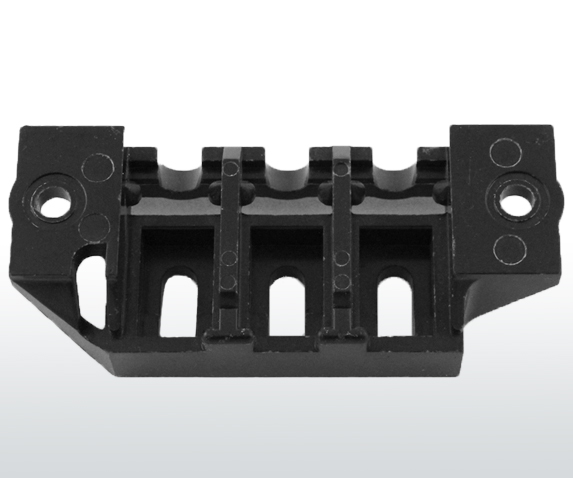

In addition to outdoor environments, some indoor applications can be equally as challenging. Home appliances such as washers constantly see steam when in use, using thermoset molded terminal blocks connected to wiring and harness assemblies. Using a thermoplastic or metal in this application could cause electrical failure, whereas thermoset terminal blocks are not affected even within heavy steam environments. Another interesting indoor application where thermosets are molded is low-cost kitchen or bathroom sinks. Recreational vehicles may have thermoset molded sinks to provide strength, corrosion resistance, and much lower part weight over sinks made from other materials.

Thermosets in Water-Based Applications

Other applications thermosets are increasingly being used in are direct water-based applications such as water pump housings, covers, and impellers. Marine and automotive pumps may have water or liquids continually running through the application, creating high potential for corrosive failure with metallic parts. Using thermosets in pump applications greatly reduces the risk of corrosion, and the molded parts also do not require costly secondary painting or finishing as a metallic component may need. Although porous, thermosets have low water absorption properties over thermoplastics. Thermosets will not swell as a thermoplastic would in direct water-based environments, reducing wear and durability concerns on the end-part.

Comments are closed