Why Thermoset Parts Need to be Deflashed

“Deflashing” is a secondary manufacturing process in thermoset molding to remove excess material or “flash” from molded parts. Whereas a thermoplastic molded part is molded as a finished part ready to ship, thermoset molded parts must be flashed with excess material around the part to avoid molding defects and short shots. The parts can be deflashed manually by hand using a file or ceramic knife, or it can be in a more automated, batch process by tumbling the parts in deflash equipment that blasts media at the part to remove the flash. Media used to deflash the parts in deflash equipment includes thermoplastic media, walnut shells, or other abrasive materials that is strong enough to remove the part without damaging any part details or dimensions.

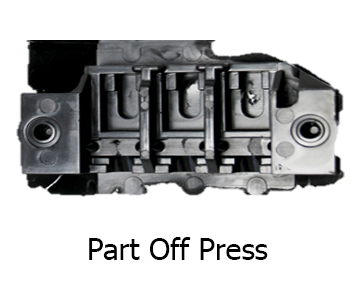

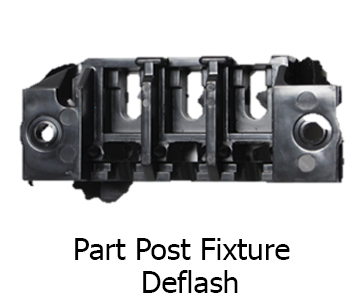

Below are representations of thermoset molded parts off a mold with full flash, then after initial flash has been removed by hand or with a fixture, and finally with the finished parts having gone through an automated batch tumble process showing the part with all flash removed.