Woodland Blog

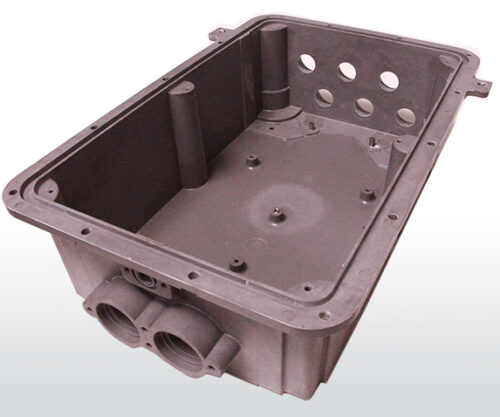

Use of Thermosets in Corrosive Environments

With superior material property performance over thermoplastics, thermosets are an excellent material option for applications exposed to challenging environments. One of the main material benefits molded thermosets exude is strong resistance to corrosion and rust. Whether an application is exposed to outdoor conditions with high humidity or moisture, or used to house electrical components, thermosets […]

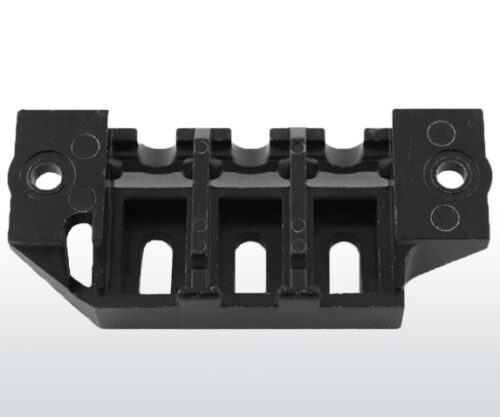

Using Inserts in Thermoset Molding

Using Inserts in Thermoset Molding Injection molders and OEMs have been using various styles of inserts in their plastic parts and product applications to mechanically fasten separate components together for quite some time. Thermoset molded parts are no different. Depending on the application type, environment the application is used in, and geometries of the molded […]

Thermoset vs. Thermoplastic

Many potential customers are unsure whether a thermoplastic or thermoset molding material is best for their product application. The answer depends on the material property requirements of the product application. How the product is used, and the environment the product operates in are two of the biggest variables to determine if a thermoset or thermoplastic […]

Metal-to-Thermoset Conversions

As engineers and product designers continue to try and maximize efficiency and minimize costs in existing or new product applications, thermoset composites are increasingly becoming a material conversion option for performance-sensitive, price-conscious applications that have traditionally been manufactured in metallic materials. Whether converting for cost, performance, or commercial reasons, thermoset composites are allowing engineers to […]

Thermoset Injection Molding – What Is It, What To Expect?

Many of our customers or prospective customers ask about thermoset molding. What is it? Can you injection mold thermosets? How does it differ from thermoplastic injection molding (ie, nylon, ABS, PP)? How does it process?

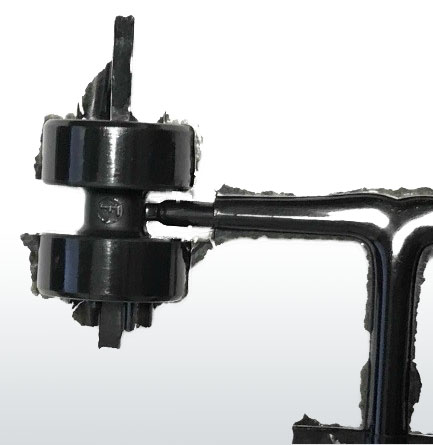

Deflashing in Thermoset Molding

As a custom thermoset molder, Woodland Plastics sees a vast variety of product applications and components we mold for our customers. Regardless of whether the application is a large or small part, a basic part design or components with complex geometries; thermoset molded parts will always require a deflashing method to eliminate excess flash around […]

Injection Molding with Thermosets

Thermoset parts and components may be manufactured in similar molding processes as thermoplastics such as nylon, ABS, and polypropylene. The most popular molding processes for thermosets are injection, compression, injection-compression hybrid, transfer, and insert molding. Each molding process offers various benefits and disadvantages which molders and OEM’s must compare with their product requirements before building […]

To Post-Bake or Not To Post-Bake: The Inside Scoop on Post-Baking Phenolics

With decades of thermoset molding experience including injection molding for phenolic resins, or phenolic molding compounds, a common question asked by our customers is if their application should be post-baked. The answer: “It depends”. While post-baking molded phenolics may provide increased property performance, it is not needed or recommended for all phenolic molding applications.

Thermoset 101: How Are Thermosets Molded?

Thermosets are processed in similar functions to thermoplastics such as nylon, ABS, polypropylene, etc. Thermosets may be injection molded, compression molded, injection-compression molded, or transfer molded. Additionally thermosets can utilize molded-in inserts within the molding process.

Manufacturing ERP Software for Real-Time Production Data

What is a manufacturing ERP system? Manufacturing ERP is a business management software system that streamlines manufacturing operations and data to provide a real-time view of its core business processes. While manufacturers can tailor their own ERP applications to relevant avenues of their manufacturing operations, some common applications included in a manufacturing ERP system may […]